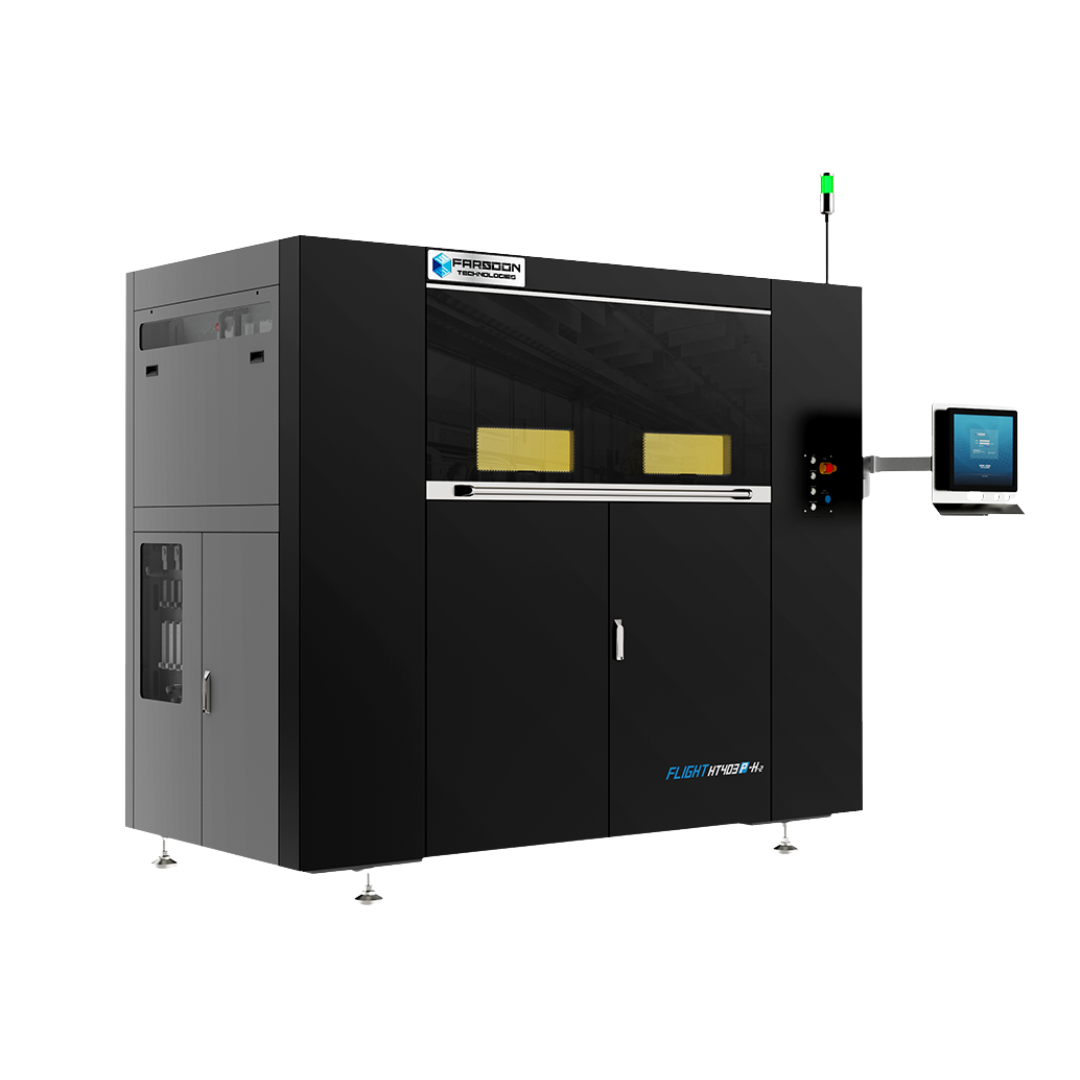

FLIGHT® 403P-2 Dual Laser

The first machine manufacturers to develop production-targeted industrial LPBF solutions using robust Fiber Lasers. Developed to address the requirements of industrial-scale series production using LPBF technology, increasing the manufacturing turn-over rate and accelerating the product-to-market cycles, the dual-laser configuration for FLIGHT® technology takes advantage of two powerful 300-watt Fiber lasers and two dynamic optical systems, creating two ultra-fine laser spots with fast scanning speed of up to 20m/s (66ft/s) for each.

Description

Fiber

Equiped with powerful fiber lasers in place of the standard CO2 lasers, Flight® 403P-2 Series is capable of delivering greatly increased power to the powder bed. Due to the more robust and stable nature of a fiber laser system, Flight® Technology also provides improved laser longevity which is key when considering ROI for manufacturing applications.

Fast

With robust laser power, improved energy distribution to the material, and smaller laser spot size, Flight® Technology is able to achieves the full sintering of powder in a significant short amount of time. With scanning speed of over 20m/s (66 ft/s) as well as the large build volume, Flight® 403P-2 Series is able to achieve extreme sintering speeds that pushes the additive manufacturing productivity to a new level.

Open Platform

Like all Farsoon systems, FLIGHT® 403P-2 Series is offered with fully open machine parameters and unlocked matreial choices. In addition with its increased power and energy absorption characteristics Flight® Technology will be capable of accessing a much different range of process-able materials and operational flexibility as compared to standard laser sintering systems, which allows for increased freedom for future AM material and application development.

Dual-Laser Configuration

To further increase the manufacturing turn-over rate, the dual-laser configuration for Flight® technology takes advantage of two powerful 300-watt Fiber lasers and two dynamic optical systems, creating two ultra-fine laser spots with fast scanning speed. The new dual-laser configuration can offer significantly 50-90% higher production volume rate compared to the single laser configuration of Flight® Technology, and 3 to 4 times production yield compared to a single CO2 laser machine.

SpecificationsTechnical Data FLIGHT® SS403P FLIGHT® HT403P External Dimensions (L×W×H) 2540×1320×2220 mm ( 100.0×52.0×87.4 in ) '' Build Cylinder Size1 (L×W×H) ) 400×400×450 mm ( 15.7 × 15.7 × 17.7 in ) or 400×400×540 mm ( 15.7 × 15.7 × 21.3 in ) '' Net Weight Approx. 3100 kg (6834.3 lb) '' Laser Type Fiber Laser, 1×300W '' Scanner High-precision three-axis galvo system '' Layer Thickness 0.06 - 0.3 mm ( 0.0024-0.0118 in ) '' Volume Build Rate2 Up to 6 L/h '' Scanning Speed Max. 20 m/s ( 65.6 ft/s ) '' Max. Chamber Temperature 190°C ( 374 ℉ ) 220°C ( 428 ℉ ) Thermal Field Control Eight-zone heater & intelligent temperature control systems '' Temperature Regulation Continous real-time build surface temperature monitoring & optimization '' Operating System 64 bit Windows 10 '' Comprehensive Software BuildStar, MakeStar® '' Data File Format STL '' Key Software Features Open machine key parameters, real-time build parameter modification, three-dimensional visualization, diagnostic functions '' Inert Gas Protection Nitrogen '' Power Supply EUR/China: 400V±10%, 3~/N/PE, 50/60Hz, 32A US: transformer sold with machine '' Operating Ambient Temperature 22 - 28 °C ( 71.6-82.4 ℉ ) '' Brochure